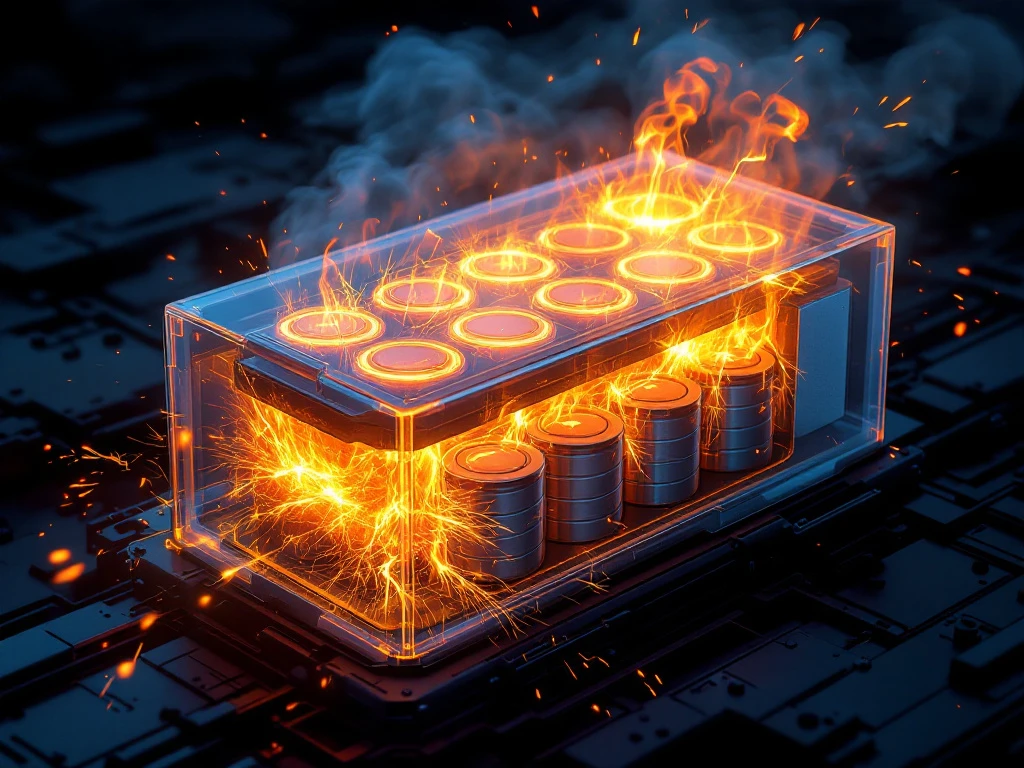

How does thermal runaway in your BESS spread between cells?

BESS thermal runaway is a dangerous condition where battery cells reach their critical thermal threshold, which varies depending on the battery chemistry often ranging from around 130°C for NMC cells to up to 250°C for LFP cells, triggering uncontrollable chemical reactions that generate more heat. This heat spreads to neighbouring cells through conduction, convection, and toxic gas emissions, creating a cascading failure that can engulf entire battery modules. Understanding how thermal runaway propagates between cells is crucial for designing safer battery energy storage systems.

What is thermal runaway and how does it start in BESS cells?

Thermal runaway occurs when a battery cell reaches its critical thermal threshold, which varies depending on the battery chemistry often ranging from around 130°C for NMC cells to up to 250°C for LFP cells. This reaction can cause fires that spread rapidly and release toxic gases such as hydrogen fluoride (HF) and carbon monoxide (CO), as well as significant volumes of highly flammable gases including hydrogen and methane, causing the electrolyte to decompose and internal chemical reactions to become self-sustaining. The cell generates more heat than it can dissipate, leading to an uncontrollable temperature rise that can reach over 800°C.

Several triggers can initiate thermal runaway in BESS cells. Physical damage from impacts or manufacturing defects can create internal short circuits, whilst overcharging forces more energy into the cell than it can safely handle. External heat sources, such as fires or faulty heating systems, can also push cells beyond their thermal limits. Internal component failures, including separator breakdown or electrode degradation, create pathways for dangerous reactions.

During the onset, the battery cell experiences rapid gas generation as the electrolyte breaks down, creating pressure that may cause cell swelling or rupture. The chemical reactions become exothermic, meaning they produce heat rather than consume it, creating a feedback loop where rising temperatures accelerate further decomposition. This process is particularly concerning in lithium-ion batteries, which are the most common technology used in modern BESS installations.

How does thermal runaway spread from one cell to neighbouring cells?

Thermal runaway spreads through three primary mechanisms: direct heat conduction through physical contact points, convective heat transfer via hot gases, and exposure to toxic emissions that can damage adjacent cell materials. The propagation typically follows predictable pathways based on the battery system’s physical layout and thermal design.

Heat conduction occurs when the affected cell’s elevated temperature transfers directly through metal connections, mounting brackets, or shared structural components to neighbouring cells. This direct thermal pathway can raise adjacent cells to their own thermal runaway threshold within minutes, depending on the thermal mass and conductivity of the connecting materials.

Convective heat transfer happens when hot gases generated during thermal runaway circulate around nearby cells. These gases, which can reach temperatures exceeding 500°C, create localised hot spots that heat neighbouring cells from the outside. The gas emissions also contain corrosive compounds that can damage cell casings, potentially creating new failure points.

Cell proximity plays a critical role in propagation speed. Cells packed tightly together with minimal spacing experience faster heat transfer, whilst those separated by thermal barriers or air gaps have more time before reaching dangerous temperatures. The thermal runaway process can spread through an entire battery module in as little as 5-15 minutes without proper containment measures.

What factors determine how fast thermal runaway spreads in a BESS?

The propagation speed depends on battery chemistry, cell spacing, thermal management effectiveness, and environmental conditions. Lithium iron phosphate (LFP) batteries typically spread thermal runaway more slowly than nickel manganese cobalt (NMC) chemistries due to their inherently more stable thermal characteristics.

Cell spacing is crucial for controlling spread rates. Densely packed cells with minimal air gaps allow rapid heat transfer, whilst cells separated by 10-20mm or more provide additional time for detection and response systems to activate. The thermal mass of surrounding materials also affects propagation speed – lightweight plastic housings heat up quickly, whilst metal enclosures with higher thermal mass can absorb more heat before reaching critical temperatures.

Active thermal management systems significantly influence spread rates. Well-designed cooling systems can remove heat faster than thermal runaway generates it in early stages, potentially containing the event to a single cell. However, once multiple cells enter thermal runaway simultaneously, even robust cooling systems may become overwhelmed.

Environmental factors such as ambient temperature, humidity, and ventilation also affect propagation. High ambient temperatures reduce the thermal margin before cells reach runaway conditions, whilst poor ventilation allows hot gases to accumulate around neighbouring cells. Wind or forced air circulation can help disperse heat and gases, slowing the spread process.

How can thermal barriers prevent cell-to-cell propagation?

Thermal barriers use insulating materials and design strategies to interrupt heat transfer pathways between cells, containing thermal runaway within individual cells or small groups. These barriers work by absorbing heat, reflecting thermal radiation, or creating air gaps that slow conductive heat transfer.

Passive thermal barriers include ceramic wool, aerogel insulation, and specialised fire-resistant materials placed between cell groups. These materials can withstand temperatures exceeding 1000°C whilst maintaining their insulating properties. Some advanced barriers incorporate phase-change materials that absorb large amounts of heat during melting, providing additional thermal protection during the critical early stages of thermal runaway.

Active thermal management approaches include dedicated cooling channels, heat sinks, and emergency cooling systems that activate when elevated temperatures are detected. These systems can include liquid cooling loops that circulate coolant between cell groups, or gas-based systems that flood affected areas with inert gases to prevent oxygen-fuelled combustion.

Structural design plays an equally important role. Battery modules can be compartmentalised so that thermal runaway in one section doesn’t easily spread to others. This includes using thermally resistant separators, creating ventilation pathways for hot gas escape, and designing mounting systems that minimise conductive heat transfer between cell groups.

What are the warning signs of thermal runaway propagation in BESS?

Early detection relies on temperature monitoring, gas detection systems, and electrical parameter changes that signal thermal runaway is beginning to spread. Modern battery management systems continuously monitor these parameters and can detect anomalies before visible signs appear.

Temperature sensors throughout the battery system provide the first line of detection. Rapid temperature increases of 5-10°C per minute in individual cells or modules indicate potential thermal runaway initiation. When multiple adjacent sensors show simultaneous temperature rises, this suggests propagation is occurring between cells.

Gas detection systems can identify the toxic and flammable gases released during thermal runaway, including hydrogen fluoride, carbon monoxide, and various organic compounds. These gases often appear before visible smoke or flames, providing crucial early warning time for emergency response procedures.

Electrical indicators include sudden voltage drops, current spikes, or complete loss of communication with affected battery modules. These changes occur as internal cell structures break down and electrical connections fail. Advanced monitoring systems can detect these electrical anomalies and automatically isolate affected sections to prevent further spread.

Physical signs of propagation include visible smoke, unusual odours, and audible sounds such as popping or hissing from gas release. However, by the time these signs are apparent, thermal runaway is typically well-established and immediate emergency procedures should be implemented.

Understanding BESS thermal runaway propagation is essential for anyone involved in battery energy storage projects. Proper system design, monitoring, and emergency procedures can significantly reduce the risks associated with these powerful energy storage systems. For comprehensive risk assessment and specialised expertise in battery storage system safety and risk management, contact our team today to discuss your renewable energy project requirements and ensure optimal safety measures are in place.

Insurance and inspection needs for your BESS?

Contact us today if you want to know more about the possibilities in BESS insurance and Scope inspections.

📧 Email: support@solarif.com

☎️ Phone: +31 (0)26 711 5050