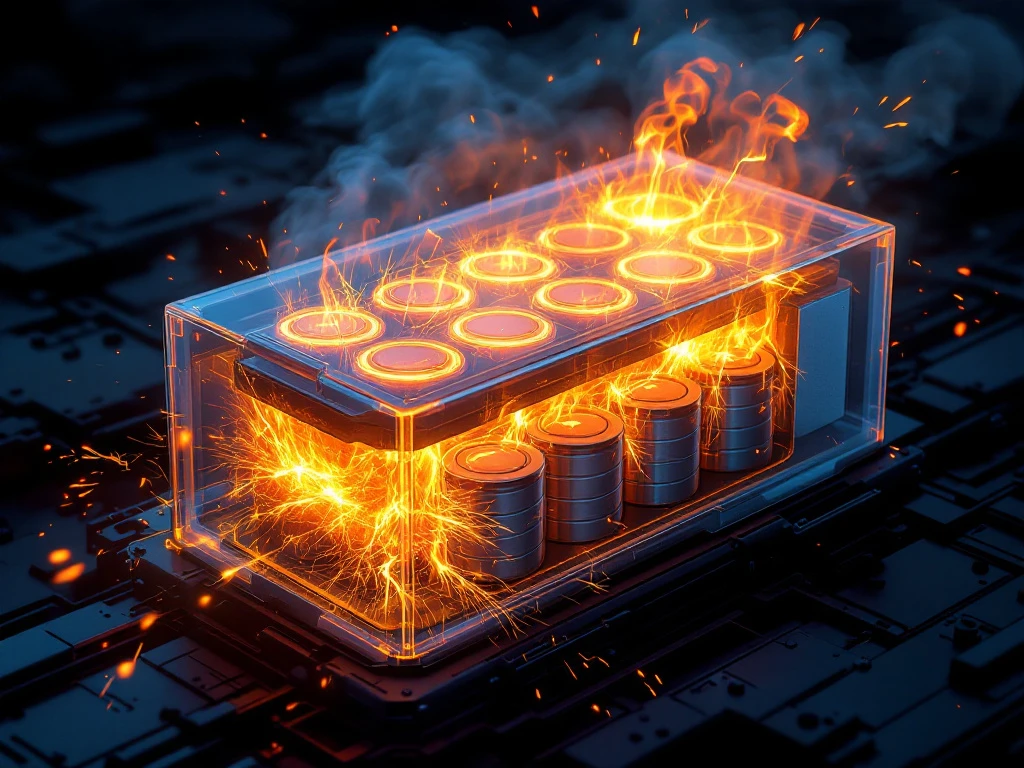

How does thermal runaway damage BESS equipment?

Thermal runaway is a dangerous condition where battery cells like in a BESS generate excessive heat in a self-sustaining cycle, leading to catastrophic damage. This occurs when internal temperatures rise beyond safe limits, causing chemical reactions that produce more heat and toxic gases. The damage spreads rapidly between cells, potentially destroying entire battery modules and creating significant safety hazards including fire and explosion risks.

What is thermal runaway in BESS equipment and why does it happen?

Thermal runaway in BESS equipment is a self-perpetuating chain reaction where battery cells generate excessive heat that triggers further heat production. This electrochemical process occurs when a lithium-ion cell’s internal temperature exceeds approximately 130°C, causing the electrolyte to break down and release flammable gases whilst generating additional heat.

The process begins when one or more triggers push a battery cell beyond its safe operating parameters. Common triggers include overcharging, which forces excessive current into already full cells, creating heat through resistance. Physical damage from impacts, punctures, or manufacturing defects can create internal short circuits that generate intense localized heating.

Environmental factors also play a crucial role. High ambient temperatures, inadequate cooling systems, or blocked ventilation can prevent proper heat dissipation. Poor battery management system (BMS) performance may fail to detect early warning signs like voltage irregularities or temperature spikes. Once initiated, the thermal runaway process becomes self-sustaining as decomposing electrolytes and separators release energy, creating a dangerous cycle that’s extremely difficult to stop.

How does thermal runaway physically damage battery cells and modules?

Thermal runaway causes systematic destruction of battery cell components through heat, chemical breakdown, and gas generation. The electrolyte decomposes first, losing its ability to facilitate ion transfer whilst releasing toxic and flammable gases including hydrogen fluoride, carbon monoxide, and various organic compounds.

The separator material, typically a thin polymer membrane, melts and fails at temperatures around 130-160°C. This creates direct contact between electrodes, causing internal short circuits that generate additional heat and sparks. Electrode materials begin degrading, with the cathode releasing oxygen that feeds combustion whilst the anode structure breaks down.

Cell swelling occurs as gases accumulate inside the sealed casing, potentially causing the cell to rupture or vent violently. The metal casing itself can reach temperatures exceeding 500°C, becoming hot enough to ignite surrounding materials. When one cell fails, the intense heat and flames spread to adjacent cells within the module, creating a cascading failure pattern that can consume entire battery packs within minutes.

What happens when thermal runaway spreads throughout a BESS system?

When thermal runaway spreads beyond individual modules, it creates cascading failures that can destroy entire BESS installations through thermal propagation. Heat spreads between adjacent battery modules through conduction, convection, and radiant heat transfer, with temperatures often exceeding 800°C in severe cases.

The domino effect accelerates as more cells enter thermal runaway, overwhelming cooling systems that were designed for normal operating conditions. Electrical connections begin failing as insulation melts and conductors overheat, potentially creating additional ignition sources. Control systems, including the BMS and power conversion equipment, shut down or fail completely as temperatures exceed their operating limits.

Structural components suffer significant damage as the intense heat warps metal housings, compromises fire-resistant barriers, and can even damage the concrete foundations of larger installations. The toxic gas emissions create additional safety hazards, requiring evacuation of surrounding areas. Fire suppression systems may struggle to contain the blaze, as lithium-ion fires burn at extremely high temperatures and can reignite even after appearing extinguished.

How much does thermal runaway damage typically cost BESS operators?

Thermal runaway damage creates substantial financial impacts through equipment replacement, operational downtime, and emergency response costs. Direct equipment replacement costs can range from hundreds of thousands to millions of pounds, depending on the system size and extent of damage propagation.

Indirect costs often exceed direct replacement expenses. Revenue losses from system downtime can be particularly severe for BESS installations providing grid services or energy arbitrage, where daily earnings may reach thousands of pounds. Insurance claims face intensive scrutiny, potentially leading to higher premiums or coverage restrictions for future policies.

Emergency response expenses include fire brigade callouts, hazardous material cleanup, and site remediation. Environmental impact assessments may be required if toxic gases or electrolyte materials contaminate surrounding areas. Long-term impacts include reduced investor confidence, stricter regulatory oversight, and potential legal liability if the incident affects neighboring properties or grid stability.

What safety systems can prevent or minimize thermal runaway damage?

Effective thermal runaway prevention requires multiple layers of protection including advanced monitoring, fire suppression, and emergency response systems. Thermal monitoring systems with sensors throughout battery modules can detect temperature anomalies before they reach critical thresholds, triggering automatic shutdowns.

Modern fire suppression technologies include water mist systems, inert gas flooding, and specialized lithium-ion fire suppressants that can cool batteries below thermal runaway temperatures. Cell-level protection circuits monitor individual battery cells for voltage, current, and temperature irregularities, disconnecting problematic cells before they affect others.

Proper ventilation design prevents toxic gas accumulation whilst helping dissipate heat during normal operations. Early warning systems integrate multiple sensors to detect the chemical signatures of thermal runaway, including specific gas emissions that precede visible flames. Emergency shutdown procedures should include automatic disconnection of electrical systems, activation of fire suppression, and immediate notification of emergency services. Regular maintenance and professional inspections help identify potential failure points before they lead to thermal runaway incidents.

Contact us today!

Understanding these thermal runaway risks is essential for BESS operators, investors, and insurance providers. Professional risk assessment and appropriate insurance coverage protect against the substantial financial and operational impacts of these potentially catastrophic events. We can advise and help you with that.

📧 Email: support@solarif.com

☎️ Phone: +31 (0)26 711 5050