Why is thermal runaway important for energy storage safety?

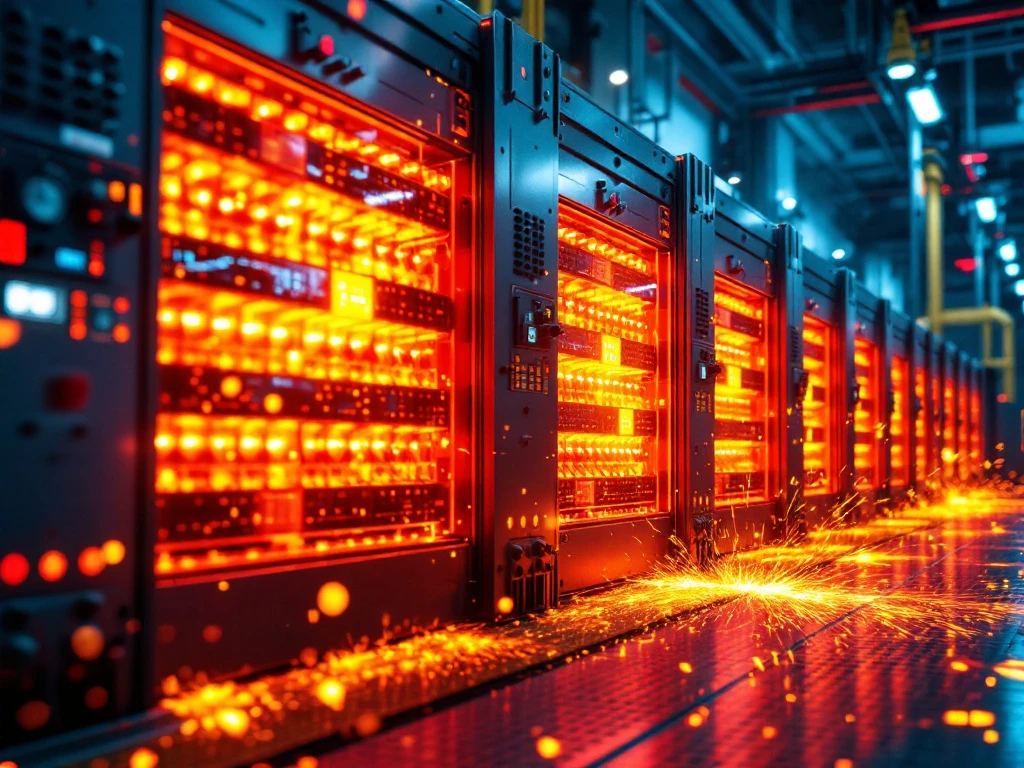

BESS thermal runaway is a dangerous chain reaction where battery cells overheat uncontrollably, potentially causing fires, explosions, and toxic gas emissions. This cascading failure occurs when internal battery temperatures exceed safe thresholds, triggering chemical reactions that generate more heat and spread to adjacent cells. Understanding thermal runaway risks is essential for safe energy storage system design and operation.

What is BESS thermal runaway and why does it happen?

BESS thermal runaway is an uncontrolled chemical reaction within lithium-ion battery cells that generates excessive heat, leading to cell failure and potential fire or explosion. Thermal runaway in lithium-ion batteries occurs when temperatures reach their critical thermal threshold, which varies depending on the battery chemistry often ranging from around 130°C for NMC cells to up to 250°C for LFP cells. This reaction can cause fires that spread rapidly and release toxic gases such as hydrogen fluoride (HF) and carbon monoxide (CO), as well as significant volumes of highly flammable gases including hydrogen and methane.

The thermal runaway process begins when one cell experiences stress from overcharging, physical damage, manufacturing defects, or extreme temperatures. As the cell heats up, its internal chemical reactions accelerate, producing more heat in a self-reinforcing cycle. The cell’s separator membrane breaks down, allowing direct contact between electrodes, which creates internal short circuits and further temperature increases.

BESS installations are particularly susceptible because they contain hundreds or thousands of closely packed battery cells. When one cell enters thermal runaway, the intense heat can trigger neighbouring cells to fail in a cascading reaction. Large-scale battery energy storage systems often use lithium-ion chemistries like NMC (Nickel Mangaan Kobalt) which, whilst offering high energy density, are more thermally sensitive than alternatives like LFP (lithium ijzerfosfaat).

The confined spaces typical in BESS containers or enclosures can trap heat and toxic gases, accelerating the spread of thermal runaway throughout the system. Poor ventilation, inadequate thermal management, or failure of cooling systems significantly increases the risk of cascading failures across entire battery modules.

What are the main safety risks of thermal runaway in energy storage systems?

The primary safety risks include intense fires reaching temperatures above 1000°C, toxic gas emissions including hydrogen fluoride and carbon monoxide, explosion hazards from flammable gas accumulation, and cascading failures that can destroy entire BESS installations whilst threatening surrounding infrastructure and personnel.

Fire hazards represent the most immediate danger, as thermal runaway produces extremely hot flames that are difficult to extinguish with conventional methods. These fires can burn for hours or days, generating temperatures that can melt metal components and spread to adjacent equipment or buildings.

Toxic gas emissions pose serious health risks to emergency responders and nearby personnel. During thermal runaway, battery cells release dangerous gases including hydrogen fluoride, carbon monoxide, and various highly flammable gases such as hydrogen and methane. These gases can be lethal in enclosed spaces and require specialised breathing apparatus for safe exposure.

Explosion risks occur when flammable gases accumulate in confined spaces and encounter an ignition source. The rapid pressure buildup can cause violent explosions, projecting debris and spreading the thermal event to previously unaffected areas of the installation.

Cascading failures represent perhaps the greatest threat to BESS operations. Once thermal runaway begins in one area, the heat and toxic gases can trigger failures throughout the entire system, potentially destroying millions of pounds worth of equipment and creating extended power outages for connected facilities.

How can thermal runaway be prevented in BESS installations?

Prevention requires comprehensive thermal management systems, careful battery chemistry selection, proper system design with adequate spacing between modules, quality installation practices, and advanced monitoring technologies that detect early warning signs before thermal runaway occurs.

Effective thermal management forms the foundation of prevention. This includes active cooling systems that maintain optimal operating temperatures, proper ventilation design to remove heat buildup, and thermal barriers between battery modules to prevent heat transfer. Many installations use liquid cooling systems or advanced air circulation to keep cells within safe temperature ranges.

Battery selection significantly impacts thermal runaway risk. LFP (lithium iron phosphate) chemistries offer superior thermal stability compared to NMC variants, though they provide lower energy density. Quality battery management systems (BMS) are essential, continuously monitoring cell voltages, temperatures, and current flows whilst preventing overcharging or deep discharge conditions.

Proper installation practices include maintaining adequate spacing between battery modules, using fire-resistant materials in construction, implementing proper grounding and electrical protection, and ensuring all connections meet manufacturer specifications. Professional installation by certified technicians reduces the risk of faults that could trigger thermal events.

Advanced monitoring technologies enable early detection of problematic conditions. Temperature sensors throughout the system, voltage monitoring for each cell group, and gas detection systems can identify developing issues before they escalate to thermal runaway. Modern BMS systems can automatically disconnect affected modules and activate cooling systems when anomalies are detected.

What safety measures should be in place for BESS thermal runaway protection?

Essential safety measures include specialised fire suppression systems designed for lithium-ion fires, comprehensive emergency response procedures, proper ventilation systems for toxic gas management, physical safety barriers, and strict compliance with relevant safety standards and regulations for energy storage installations.

Fire suppression systems must be specifically designed for lithium-ion battery fires. Water-based systems can be effective but require large quantities and proper drainage. Inert gas suppression systems using nitrogen or argon can prevent oxygen from feeding fires. Some installations use specialised cooling fluids or foam systems designed for electrical fires.

Emergency response procedures should include clear evacuation protocols, coordination with local fire services trained in BESS incidents, and procedures for isolating affected systems. Emergency responders need proper training and equipment to handle toxic gas exposure and electrical hazards present during thermal runaway events.

Ventilation design is crucial for removing toxic gases and heat during normal operation and emergency conditions. This includes both natural ventilation through properly sized openings and mechanical ventilation systems that can operate during power outages. Ventilation must prevent gas accumulation whilst maintaining appropriate operating temperatures.

Physical safety barriers include fire-rated walls between battery modules, blast-resistant construction for high-energy installations, and adequate clearances from occupied buildings. Access control systems prevent unauthorised personnel from entering hazardous areas during normal operation or emergency conditions.

Regulatory compliance involves meeting standards from organisations like IEC, UL, and local fire codes. Regular safety inspections and maintenance ensure protective systems remain functional throughout the installation’s operational life.

How do you detect thermal runaway before it becomes dangerous?

Early detection relies on continuous temperature monitoring throughout battery modules, gas detection systems that identify thermal runaway byproducts, voltage and current monitoring for electrical anomalies, and advanced battery management systems with predictive algorithms that can identify developing thermal events before they escalate.

Temperature monitoring provides the most direct indication of developing thermal runaway. Multiple temperature sensors within each battery module and pack can detect localised heating before it spreads. Modern systems use thermal imaging cameras or distributed temperature sensing to provide comprehensive coverage of large installations.

Gas detection systems can identify thermal runaway in its early stages by detecting trace gases released as cells begin to fail. Sensors for hydrogen, carbon monoxide, and organic vapours provide early warning before visible smoke or flames appear. These systems can trigger automatic responses including ventilation activation and system isolation.

Electrical monitoring through advanced BMS systems tracks cell voltages, pack currents, and internal resistance changes that may indicate developing problems. Sudden voltage drops, unusual current patterns, or resistance increases can signal cell degradation that might lead to thermal runaway.

Predictive algorithms analyse patterns in temperature, electrical, and environmental data to identify conditions that historically precede thermal events. Machine learning systems can recognise subtle changes in system behaviour that human operators might miss, providing increasingly sophisticated early warning capabilities.

Integration of multiple detection methods provides the most reliable protection. When temperature, gas, and electrical monitoring systems all indicate developing problems, automated safety systems can isolate affected areas, activate suppression systems, and alert operators before thermal runaway becomes uncontrollable.

Understanding BESS thermal runaway risks and implementing comprehensive prevention and detection strategies is essential for safe energy storage operations. As battery energy storage systems become increasingly important for renewable energy integration and grid stability, proper thermal management and safety measures protect both valuable infrastructure and human lives. For businesses investing in energy storage projects, working with experienced professionals who understand these complex safety requirements ensures installations meet the highest standards for operational safety and regulatory compliance.

Don’t leave your BESS installation’s safety to chance. The risks of thermal runaway are too significant to manage without expert guidance and proper safety systems. Our team of energy storage specialists can help you implement comprehensive thermal management strategies, select the right safety equipment, and ensure your installation meets all regulatory requirements. Contact us today to discuss your BESS safety needs and protect your investment with industry-leading thermal runaway prevention and detection solutions.

Insurance and inspection needs for your BESS?

Contact us today if you want to know more about the possibilities in BESS insurance and Scope inspections.

📧 Email: support@solarif.com

☎️ Phone: +31 (0)26 711 5050